All employers have a duty of care when it comes to their workforce. You have the main responsibility of ensuring the health and safety of everyone in your workplace, including any visitors.

Correct personal protective equipment (PPE) benefits your employees, and anyone else on site of your business. Knowing that you have the right PPE is how you can ensure daily standards are maintained for any health and safety risks that may occur.

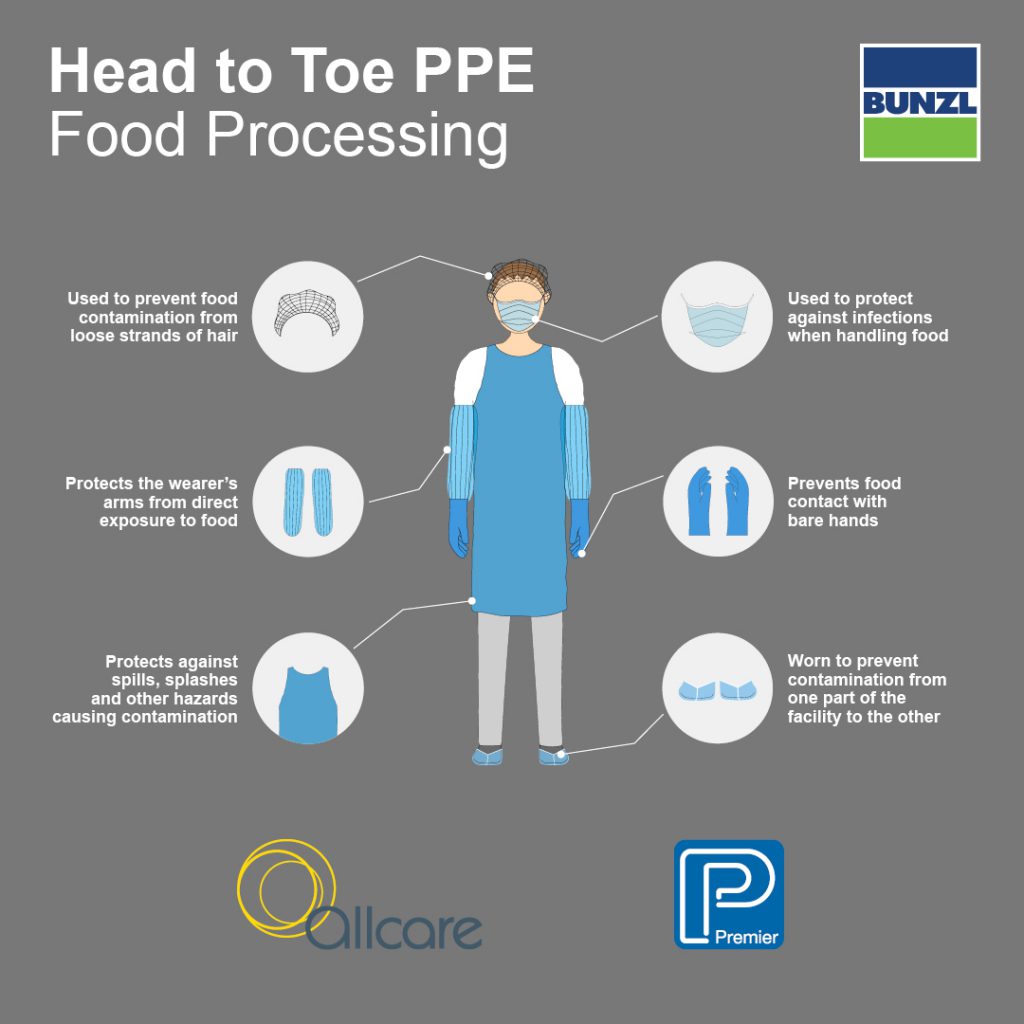

PPE itself refers to anything used or worn to minimise risk to the wearer’s safety and keep the food processing environment clean and hygienic. Common injuries such as cuts and abrasions can be prevented through correct PPE use and appropriate PPE products. When buying PPE, you should feel confident that you’ve found the best products for your workers. As with any type of clothing, it should be comfortable and functional, with the quality to ensure safety and hygiene standards are met. So, what exactly should you be looking at when it comes to PPE?

Hair Caps

In meat and food processing, hair caps should be lightweight yet fitted with a crimp to prevent any contamination. They should always completely cover the worker’s head to prevent any loose hair falling into product or getting caught in machinery. An ideal cap is made from non-linting, non-woven 100% spun-bond polypropylene, making it light-weight and breathable, with an elastic band to secure fit.

Beard Covers

The use of beard covers in food processing follows the same reasoning behind hair caps. A good quality beard cover prevents any loose hair from contaminating produce, while also minimising risk of hair getting caught in machinery. You want your beard covers to have double ear loops and an elastic band to keep them securely in place for as long as necessary.

Shoe Covers

On the processing floor, tracking outside contaminants into clean environments is a high-risk hazard. Sterile disposable shoe covers decrease contamination by ensuring that workers cannot introduce any contaminants during any stage of processing. Shoe covers should always be designed with a non-slip grip to minimise the risk of accidents when wearing them.

Disposable Aprons

Plastic aprons are used in food processing to create a barrier between workers and produce. If they get covered in contaminants, they’re easily replaced as they’re affordable and efficient. Disposable aprons with a smooth waterproof surface will protect clothing while still being lightweight, making them perfect for use in meat and food processing.

Disposable Gloves

Disposable gloves play a critical part in infection prevention by providing a physical barrier between the wearer and physical hazards such as bacteria and viruses. Single use gloves should be changed frequently throughout the day, as they can become contaminated and pose a risk of spreading infectious material around the workplace and put workers and others at risk. Nitrile examination gloves are specifically designed for general use in healthcare and commercial cleaning environments.

Mesh Gloves

Mesh gloves offer protection against hand knives, motorised blades and scissors. Injuries to the hands are the most common workplace injury[1] so ensuring you have the best mesh gloves for your workplace is important. Acting as a barrier between an employee’s hands and the blade, mesh gloves should be made from impervious material such as stainless steel. They should also hold-up against the heavy-duty cleaning required in food processing without compromising their protection or comfort.

Rubber Gloves

The use of rubber gloves over mesh gloves in meat and food processing means ensuring that no contaminates can get caught in the mesh. Rubber gloves are used to protect workers from injury and contamination and provide protection from moisture. Any rubber gloves being used in meat and food processing should be strong, durable and comfortable to wear.

The aim of PPE in the food processing industry plays a core role in reducing hazards and ensuring workplace safety. As an employer your primary duty of care under the Work Health and Safety (WHS) act is to ensure that your workers, or any other relevant parties, are not exposed to safety and hygiene risks arising from your business. That means makings sure your PPE is up to standard. High quality PPE ensures that workers are safe, produce going into market is protected, and your business is successful.

After all, a business’s most valuable assets are its employees and the customers they serve.