In March this year, the selling, supplying or distribution of expanded polystyrene cups, bowls, plates and clamshell containers was officially banned in South Australia. This move was built on legislation introduced in 2021 – the first of its kind in the country – which prohibited the sale or use of certain single-use plastics in the state. Since then, several states and territories have committed to phasing out single-use plastics over the coming years, with the ACT, Queensland, NSW and WA having already outlawed the sale and distribution of certain products.

Last year, New Zealand also announced it would ban some single-use plastics by 2025. All of which signals a new phase for the two countries in the fight to dramatically reduce waste. In particular, how this widespread single-use plastics ban will prevent the creation of certain types of waste in the first place.

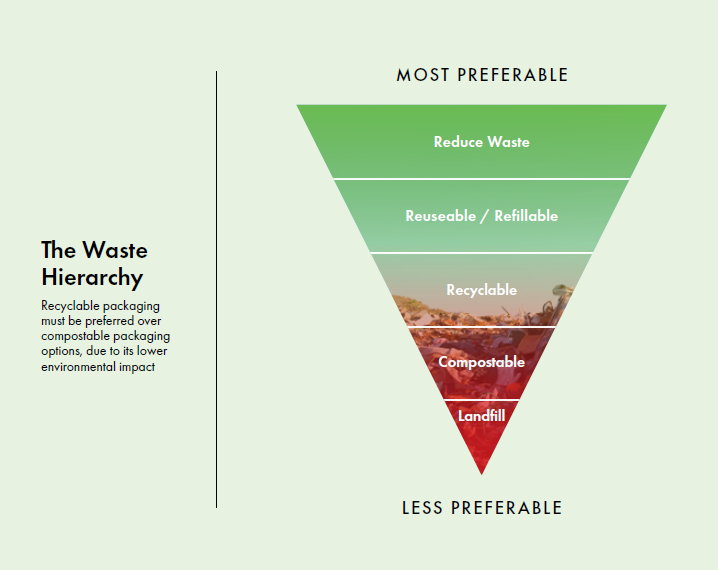

This ties neatly into the waste hierarchy – a theoretical model for reducing waste and using resources efficiently which can be applied across multiple industries. In short, the hierarchy is a quick reference guide for businesses and industry leaders, and is organised according to what waste-management option is best for the environment. Unsurprisingly, the prevention or reduction of waste sits at the top of the hierarchy as the best-practice solution, while throwing waste into landfill, considered the worst option, resides at the bottom.

And packaging is one area where the waste hierarchy is especially relevant for all businesses, regardless of the industry. As an example of preventing waste, companies should seek to avoid using any unnecessary materials in their packaging, and try to reduce existing packaging where possible. For instance, if your business uses packaging, you can ask yourself questions such as, “Could a thinner or lighter material be used instead?” And “Can any components be cut out?”

If prevention or heavy reduction aren’t viable, the next best option is to use packaging or containers that are reusable and refillable to preserve the value of the packaging material. After this, according to the hierarchy, using recycled – and recyclable – materials for your packaging is preferable and helps to build a circular economy. This means opting for recyclable cardboard to package food products or including recyclable rPET (recycled polyethylene) plastics for cold cups, drink bottles and lunch bags .

No matter what industry you are in, recycled and recyclable packaging helps to conserve resources, and in most cases will serve the same function as packaging made from virgin materials. All in all, you should look to use post-consumer recycled material and postindustrial recycled material over reworked and virgin materials, though this is not always possible.

The next preferred step down on the hierarchy is to make packaging from renewable sources – in particular, using materials that are Forest Stewardship Council certified or Programme for the Endorsement of Forest certified. And then, if the packaging is compostable and sent to composting facilities, that is an improvement on the bottom rung of the hierarchy: sending waste to landfill.

As more companies examine their waste management strategies, Bunzl is committed to avoiding products with unnecessary or excessive packaging. The hope is that the hierarchy will spur more businesses to take action, as well as providing a solid set of cross industry guidelines.