With food safety being vital in kitchen and catering services, disposable gloves are a necessary component of Personal Protective Equipment (PPE) to prevent cross-contamination and the spread of infection in the workplace.

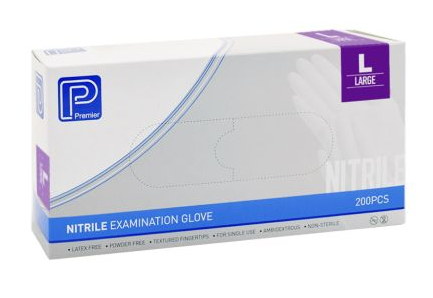

Disposable gloves have evolved over the years with three main material types dominating today’s food-handling industries. From nitrile to classic latex or the more common vinyl, each material provides respective advantages for their intended use. However, in recent years nitrile has quickly risen to the top of businesses’ preferred materials.

Originally created to be used in medical and examination applications, nitrile gloves were developed by American inventors Neil Tillotson and Luc DeBecker in the 1980s. Since then, the slow-to-acceptance product has become an industry standard due to its strength and comfort, and has evolved to be used across various industries including food processing, commercial catering and hospitality.

Made from synthetic rubber, which involves the mixing of two synthetic polymers in the manufacturing process, nitrile gloves have triple the puncture resistance of latex, a higher chemical resistance than other material alternatives and are less likely to cause its user an allergic reaction. There are a bevy of reasons nitrile gloves might have the upper hand when it comes to your business, including:

• Greater resistance to fats, oils, solvents and acids.

• Highly tactile and allows users to perform tasks with precision and ease.

• Superior puncture and tear resistance.

• Proven to be physically strong, which makes them better for higher-risk applications that require longer durations of use.

• The synthetic nature creates a longer shelf life when compared to natural rubber or latex gloves.

• Provide superior barrier protection against many chemicals and petroleum-based products.